surface grinding machine pdf

Cordless High-Speed Saw. A surface grinder is a machine tool used to provide precision ground surfaces either to a critical size or for the surface finish.

M820 Manual Surface Grinding Machine Manual Grinding Machine Factory In China

Hard turning milling drilling.

. Radius internal cylindrical. Flat and profile grinding machines. These papers are also written according to your lecturers instructions and thus minimizing any chances of plagiarism.

RECIPROCATING SURFACE GRINDING MACHINE for fastening the workpiece to the table. Capable of achieving high quality cutting tools with excellent surface finish higher accuracy and controlled runout - ANCAs new premium machine delivers batch consistency from tool number one to one thousand. Definition Diagram Parts Working Advantages Disadvantages and Applications PDF Drilling Machine is used to make circular holes on the components with the help of Drill bits.

Saws Core Drills. Whereas in Todays article we. DDRX is inclined to occur in the upper part of a ground surface due to more plastic deformation and higher temperature.

A taper pin is a self tightening device due to the shallow angle of the taper. Production external cylindrical grinding machines. Definition Diagram Parts Working Advantages Disadvantages and Applications PDF Drilling Machine is used to make circular holes on the components with the help of Drill bits.

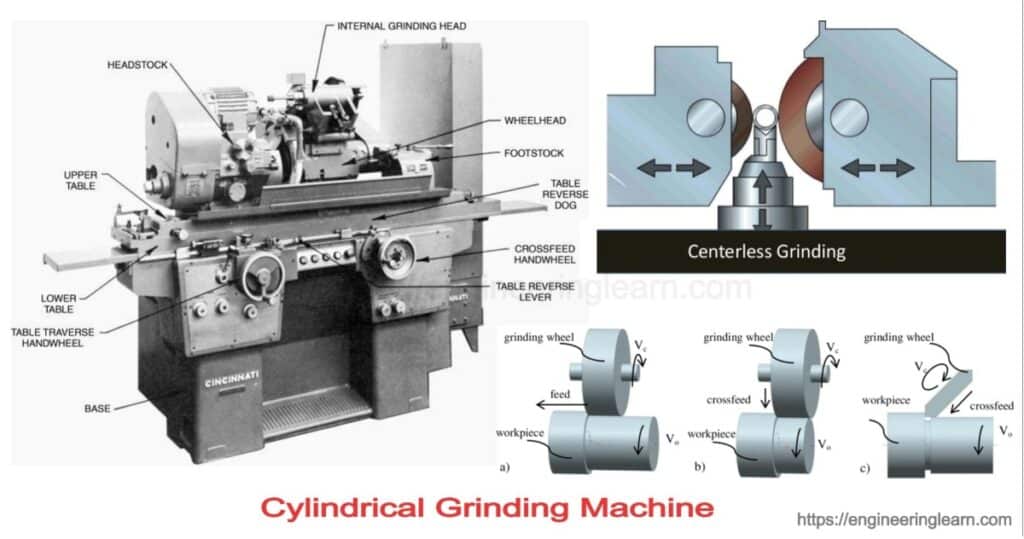

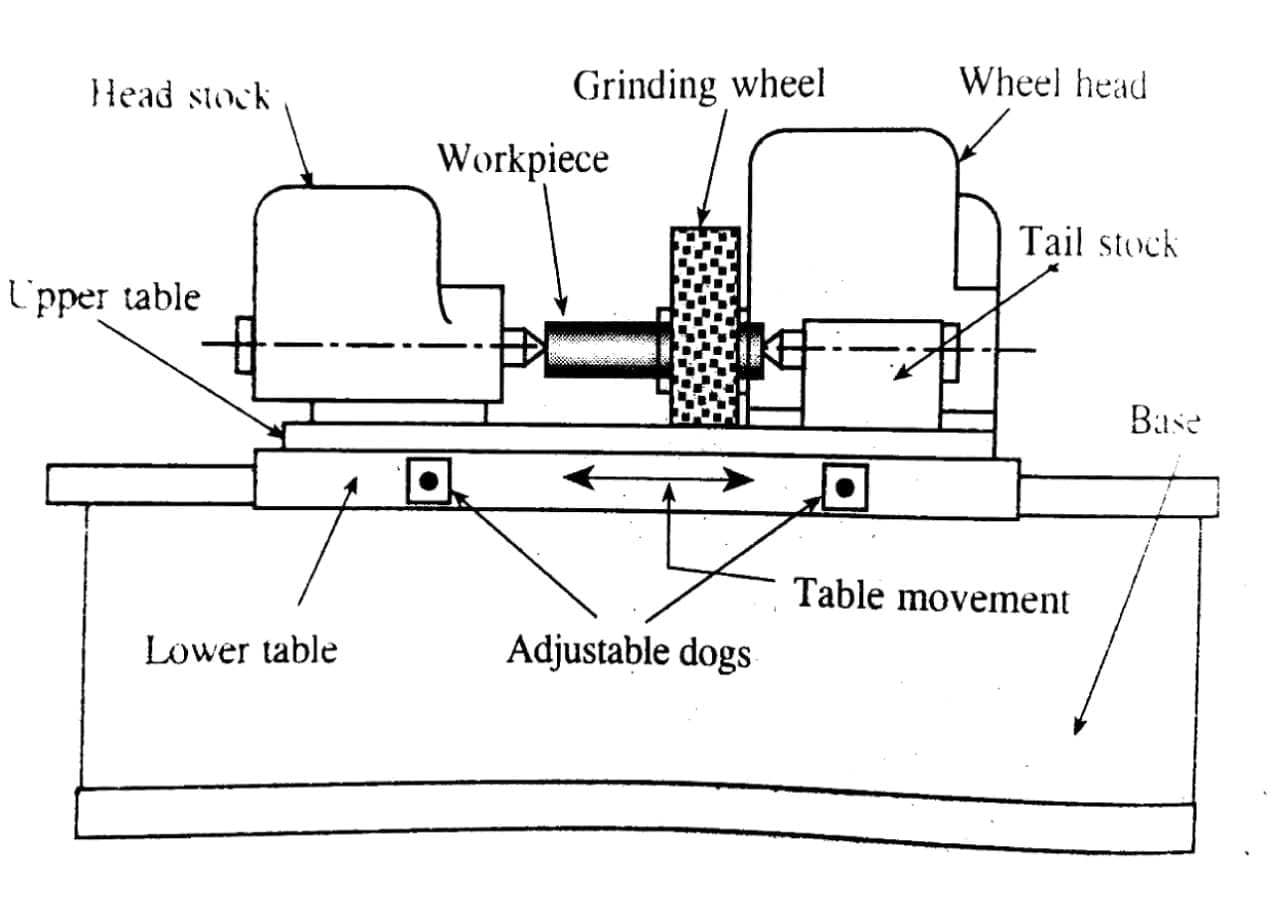

It is one of the most common types of CNC machine that have built-in tools for drilling and cutting. Most of the CNC milling machines are available in 3 to 6-axis configurations. The cylindrical surface is grinded with a machine in which grinding wheel is fitted on the shaft of a free electric motor.

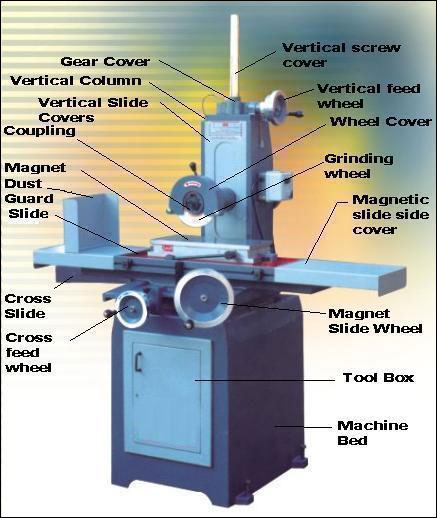

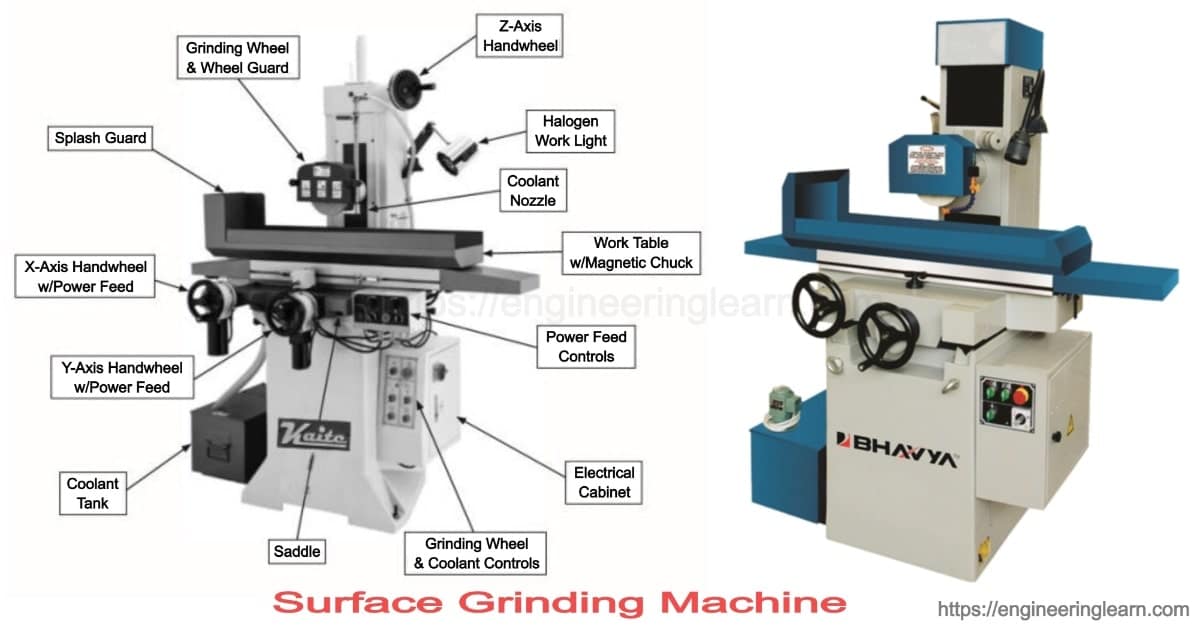

Bench and Pedestal Grinders. A suitable grinding wheel may be selected for surface grinding operation. A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it removes the unwanted material to get the desired surface finish correct size and accurate shape of the workpiece.

In the last article we had discussed the Drilling Machine Surface Grinding Machine Milling Machine lathe machine etc. Get ready for the ULTRA experience. Tool and Cutter Grinding.

For 3-year terms which are renewable. Tool and Cutter Machine. The Institute comprises 33 Full and 13 Associate Members with 12 Affiliate Members from departments within the University of Cape Town and 12 Adjunct Members based nationally or internationally.

In the last article we had discussed the Drilling Machine Surface Grinding Machine Milling Machine lathe machine etc. In the last article we had discussed the Drilling Machine Surface Grinding Machine Milling Machine lathe machine etc. 2 Both cDRX and dDRX mechanisms govern Al grain refinement in grinding of AlSiCp MMCs.

The workpiece is securely fixed on a table called platen and. Definition Diagram Parts Working Advantages Disadvantages and Applications PDF Drilling Machine is used to make circular holes on the components with the help of Drill bits. Working principle of Grinding Machine.

They may be driven into the tapered hole such that removal can only be done with a hammer and punchThey are sized by a number sequence for example a No4 reamer would use No4 taper pins. All our clients are privileged to have all their academic papers written from scratch. Production internal cylindrical grinding machines.

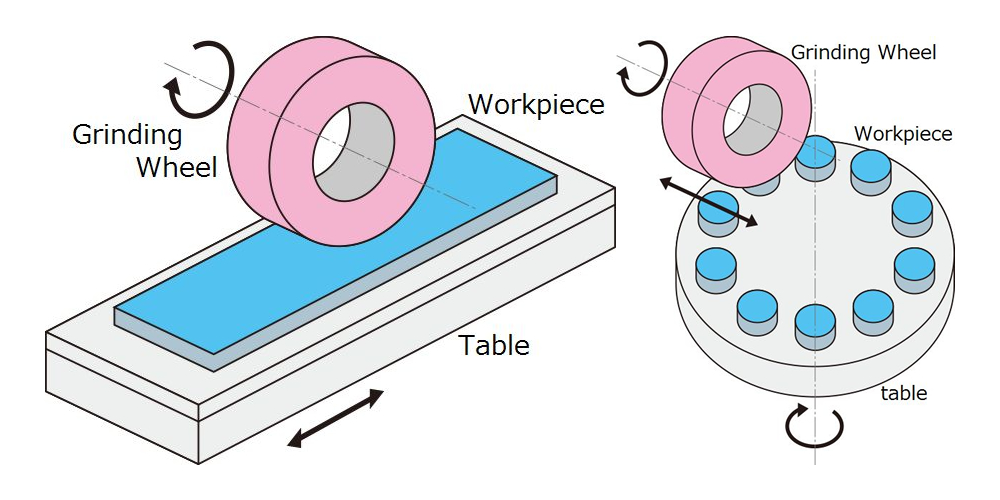

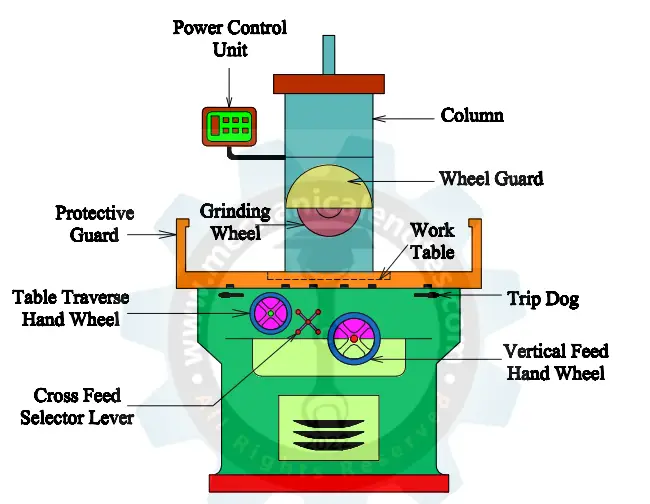

Vertical Spindle Surface Grinder. A grinding dresser or wheel dresser is a tool to dress slightly trim the surface of a grinding wheelGrinding dressers are used to return a wheel to its original round shape to true it up to expose fresh grains for renewed cutting action including cleaning away clogged areas or to make a different profile cross-sectional shape on the wheels edge. In this type of grinders the grinding wheel is fitted on the machines work table which can be given crossfeed and the entire surface of the job can be grinded.

The grinding wheel is made to revolve with the spindle and is fed up and down. So when we start the electric motor the motor rotates at a certain rpm 150-15000 RPM it may change according to the types of. Workpieces are fastened to the workpiece and wheel.

In a grinding machine there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley. It can machine workpieces with a maximum weight of 20kg 44lbs. Adjunct membership is for researchers employed by other institutions who collaborate with IDM Members to the extent that some of their own staff andor postgraduate students may work within the IDM.

The working principle of a grinding machine is quite easier to understand. These are of the following three kinds. A machine tool is a machine for handling or machining metal or other rigid materials usually by cutting boring grinding shearing or other forms of deformationsMachine tools employ some sort of tool that does the cutting or shaping.

56 Axis grinding centre. The planer is a machine tool designed to produce plane and flat surface on a workpiece which is too large or too heavy. A higher grinding speed improves surface quality which is evidenced by the reduced grinding scratches surface pits and surface roughness.

The materials are located inside a milling CNC machine after which the computer will lead the tools to drill or cut them. They are commonly placed with road marking machines also referred to as road marking equipment or pavement marking equipmentThey can also be applied in other facilities used by vehicles to mark parking spaces or designate areas for other uses. This machine is used to produce gears like spur gear and is also.

ANCAs new premium machine delivers batch consistency from tool number one to one thousand. Grinding can also be done correctly out of roundness of the hole. Both internal and external surface of a workpiece may be ground by using a.

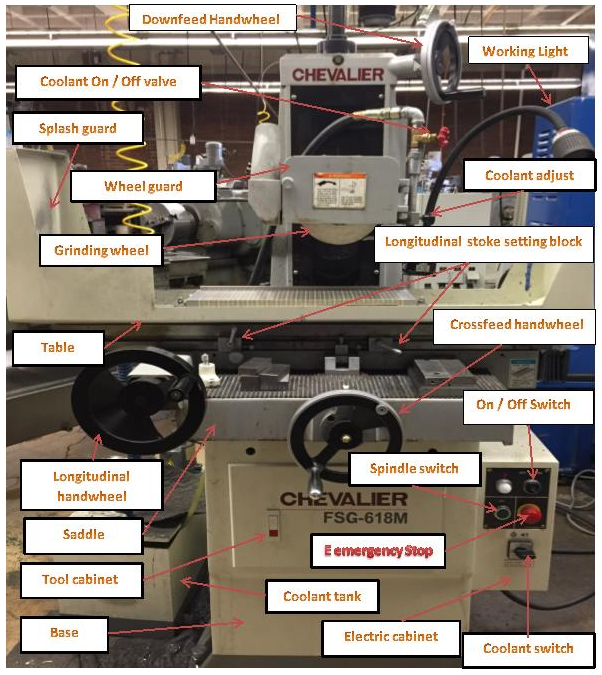

All our academic papers are written from scratch. A grinding machine often shortened to grinder is a power tool or machine tool used for grindingIt is a type of machining using an abrasive wheel as the cutting toolEach grain of abrasive on the wheels surface cuts a small chip from the workpiece via shear deformation. This grinding machine has an internal pump and piping network for The reciprocating surface grinding machine is a horizontal-automatic application and recirculation of a coolant to the type surface grinding machine.

Truing Dressing. Road surface marking is any kind of device or material that is used on a road surface in order to convey official information. Grinding is the operation of removing the metal in the form of minute chips by feeding the work against a rotating abrasive wheel known as the grinding wheel.

The typical precision of a surface grinder depends on the type and usage however 0002 mm 00001 in should be achievable on most surface grinders. Grinding operation may be performed in a drilling machine to finish a hardened hole. The S20 is a universal cylindrical grinding machine for small workpieces It has a distance between centres of 400mm 1575 650mm 256 and a centre height of 100mm 394.

All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Grinding is used to finish workpieces that must show high surface quality eg low surface. A precision tapered reamer is used to make a tapered hole to later receive a tapered pin.

M820 Manual Surface Grinding Machine Manual Grinding Machine Factory In China

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Cylindrical Grinding Machine Working Parts Types Uses

Surface Grinding Machine Saddle Type Manual Seedtec Machinery Co Ltd

Cylindrical Grinding Machine Working Parts Types Uses

Guru Arjan Machine Tools Surface Grinder Machine Surface Grinding Machine Surface Grinding Machine Manufacturer

8 Types Of Grinding Machine Parts Working Principle Grinding Wheel Complete Details Engineering Learn

Cylindrical Grinding Machine Types Process Working Principle Engineering Learn

Various Grinding Methods A L M T Corp

Grinding Machine Definition Parts Working Principle Operation Advantages Application Notes Pdf

Chapter 5 Surface Grinder Manufacturing Processes 4 5

14 Types Of Grinding Machines Working Diagram Pdf

M820 Manual Surface Grinding Machine Manual Grinding Machine Factory In China

14 Types Of Grinding Machines Working Diagram Pdf

Surface Grinder Types Of Grinders How They Work

Hydraulic Circuit For Surface Grinding Machine Explained In Details Engineering Arena

Types Of Surface Grinding Machine With Diagram Explained

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

Surface Grinding Machine Types Parts Working Procedure Engineering Learn